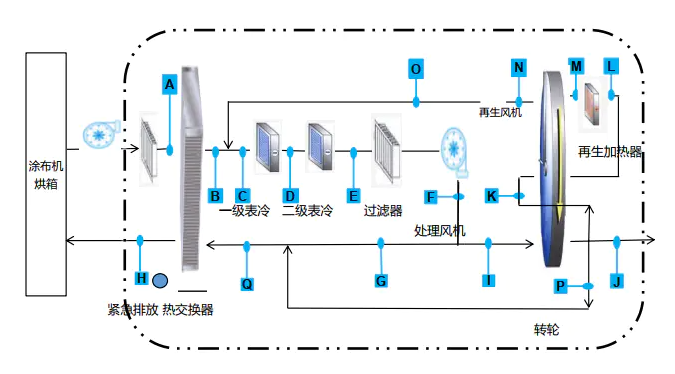

Coating machine waste gas NMP organic solvent waste heat recovery heat exchangeFlow chart:

Applications:

This equipment is suitable for recycling NMP organic solvents in the exhaust gas discharged by coating machines in the lithium battery industry, helping users achieve environmentally friendly emissions and recycle resources. This device has a simple structure and can achieve green and safe emissions without making any changes to existing production equipment, eliminating environmental concerns, reducing waste and saving energy.

Product principle:

Solvent Recovery:A primary cooling recovery device (waste heat recovery device, cooling water cooler, chilled water cooler) is used to condense part of NMP from the air. After being treated by a single-stage NMP adsorption wheel, the concentration of NMP organic solvent in the purified exhaust gas can be reduced to below 8ppm (a 1ppm NMP emission concentration can be achieved through a two-stage NMP adsorption wheel). After the exhaust gas is concentrated to a certain concentration, the NMP can be condensed and recovered by freezing.

Product Composition:

The unit consists of a waste heat recovery device, a cooler, a surface cooler, a fan, an adsorption wheel and a wheel regeneration system.

0 Comments